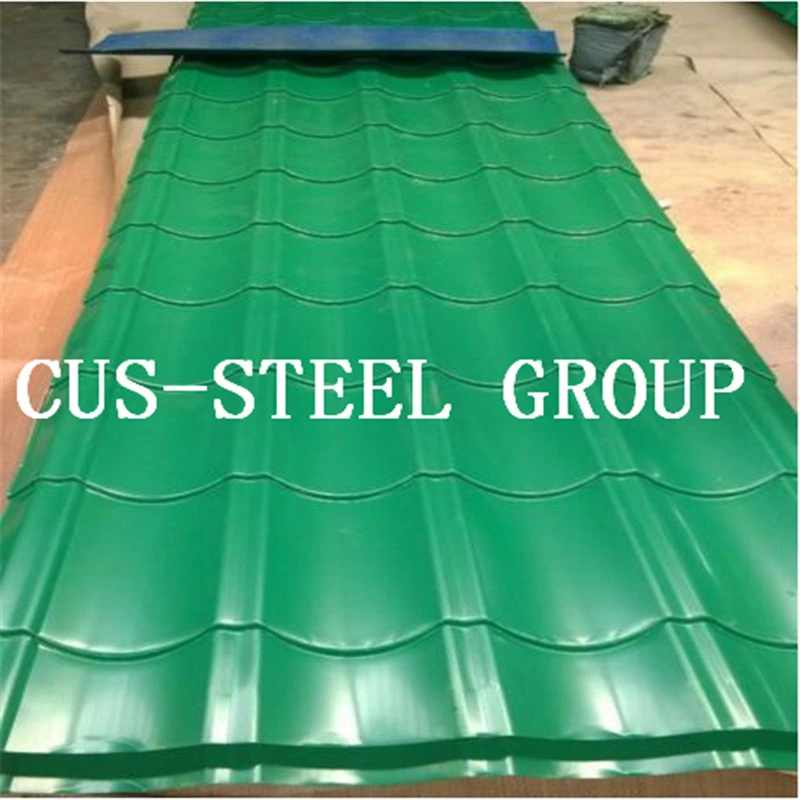

1. Tile Effect Roofing Sheets brief introduction

They are manufactured, cut to customers exact sizes and length requirements, providing 1m cover

when fitted. ie. 10 sheets will cover 10m when fitted. Two types of durable cosmetic finish our tile

effect roofing sheets are available in either a Polyester coated smooth finish or a plastisol coated

leather grained finish

2. Tile effect roofing sheets popular application

We supply quality tile effect roofing sheets suitable for all types of roofing. it offer a lightweight, cost

effective, easy to fit alternative to traditional roofing slate or clay tiles.Ideal for all types of roofing

applications from domestic garden sheds, garages and workshops, industrial units and agricultural

farm buildings

3.Tile effect roofing sheets color available

1) All standard colours are available including Terracotta, Slate Blue, Van Dyke Brown, Merlin Grey,

Juniper Green, Olive Green and Black

2) The profile has a depth of 32mm providing 5 tiles across the width of each sheet. Each individual

tile is 200mm wide and 300mm long. For example a 3 metre long sheet will consist of 50 tiles on sheet

3) All matching colour coded fixings & flashings available

4. Tile effect roofing sheets packing details

1)water proof paper covered with steel sheet on the top;Bundle by steel strip with iron pallet

2)water proof paper covered by whole steel sheet; Bundle by steel strip with iron pallet.

5. Tile effect roofing sheets installation instruction

1) Prepare the roof surface by removing any old roofing, adding roofing felt to the entire surface

2) Calculate the number of color metal roofing sheet needed.Remember that metal sheets to overlap

3) Place your first metal sheet in a corner of the roof, flush against the surface

4) Nail in the first metal sheet to the wood of the roof

5) Place the second metal sheet alongside the first with an overlap of 3 to 4 inches (or 10 cm)

They are manufactured, cut to customers exact sizes and length requirements, providing 1m cover

when fitted. ie. 10 sheets will cover 10m when fitted. Two types of durable cosmetic finish our tile

effect roofing sheets are available in either a Polyester coated smooth finish or a plastisol coated

leather grained finish

2. Tile effect roofing sheets popular application

We supply quality tile effect roofing sheets suitable for all types of roofing. it offer a lightweight, cost

effective, easy to fit alternative to traditional roofing slate or clay tiles.Ideal for all types of roofing

applications from domestic garden sheds, garages and workshops, industrial units and agricultural

farm buildings

3.Tile effect roofing sheets color available

1) All standard colours are available including Terracotta, Slate Blue, Van Dyke Brown, Merlin Grey,

Juniper Green, Olive Green and Black

2) The profile has a depth of 32mm providing 5 tiles across the width of each sheet. Each individual

tile is 200mm wide and 300mm long. For example a 3 metre long sheet will consist of 50 tiles on sheet

3) All matching colour coded fixings & flashings available

4. Tile effect roofing sheets packing details

1)water proof paper covered with steel sheet on the top;Bundle by steel strip with iron pallet

2)water proof paper covered by whole steel sheet; Bundle by steel strip with iron pallet.

5. Tile effect roofing sheets installation instruction

1) Prepare the roof surface by removing any old roofing, adding roofing felt to the entire surface

2) Calculate the number of color metal roofing sheet needed.Remember that metal sheets to overlap

3) Place your first metal sheet in a corner of the roof, flush against the surface

4) Nail in the first metal sheet to the wood of the roof

5) Place the second metal sheet alongside the first with an overlap of 3 to 4 inches (or 10 cm)

| Name | Tile effect roofing sheets |

| Standard | GB/T12754-2006 |

| Thickness | 0.18~1.0mm |

| Width | 1000~1200mm |

| Outside diameter | MAX ¢1700mm |

| Inside diameter | ¢ 508/610mm |

| Bending strength | 1-3T |

| Reverse impact | 6J-9J |

| Hardness | 3H |

| MEK | > 120 times (front) |

| < 120 times (back) | |

| Process speed | MAX 120m/min |

| Basic material | galvanized coil |

| Zinc coating | 40-275g/m² |

| Color | Ral No. or as your sample |

| Package | mills standard export packing, or according to the customers requirement |

| Providing capability | 150,000 tons per year |

| Use for | Color substrate, building, home appliances, transportation, auto industry, office supplies and articles for daily use |